German Aerospace Center (DLR) has started testing and developing ‘innovative’ propulsion systems based on hydrogen fuel cells with an output in the megawatt range. The center put into operation the BALIS test field in Empfingen on October 28, 2024.

Courtesy of DLR

Courtesy of DLR

Currently, such propulsion systems are not yet commercially available. In the future, they can be used for various modes of transport, according to DLR.

As part of the BALIS project, DLR is developing and testing fuel cell systems with an output of around 1.5 megawatts. Such systems could power ships in the future.

If hydrogen from renewable sources—the so-called green hydrogen—is used in fuel cells, it enables CO2-free and therefore climate- and environmentally friendly transport.

As disclosed, Germany’s Federal Ministry for Digital and Transport (BMDV) is funding the BALIS test field with €26 million.

“The opening of the test field is a decisive step on the way to climate neutrality by 2045. Transport is facing major challenges and hydrogen offers us the opportunity to develop and implement emission-free propulsion systems for different modes of transport. With targeted funding, we are supporting research and development in order to create innovative and ultimately marketable solutions. Together with industry and science, we are laying the foundations for sustainable mobility,” Hartmut Höppner, State Secretary at BMDV, said.

“The dialogue between research and industry that arises when large-scale facilities such as BALIS are set up and used is invaluable for both sides. This is because we are jointly demonstrating that new technologies are not only functional but also being developed to a size and cost-effectiveness that makes them an interesting solution for industry,” Prof. Dr.-Ing. Karsten Lemmer, member of the DLR Executive Board and responsible for innovation, transfer and scientific infrastructures, commented.

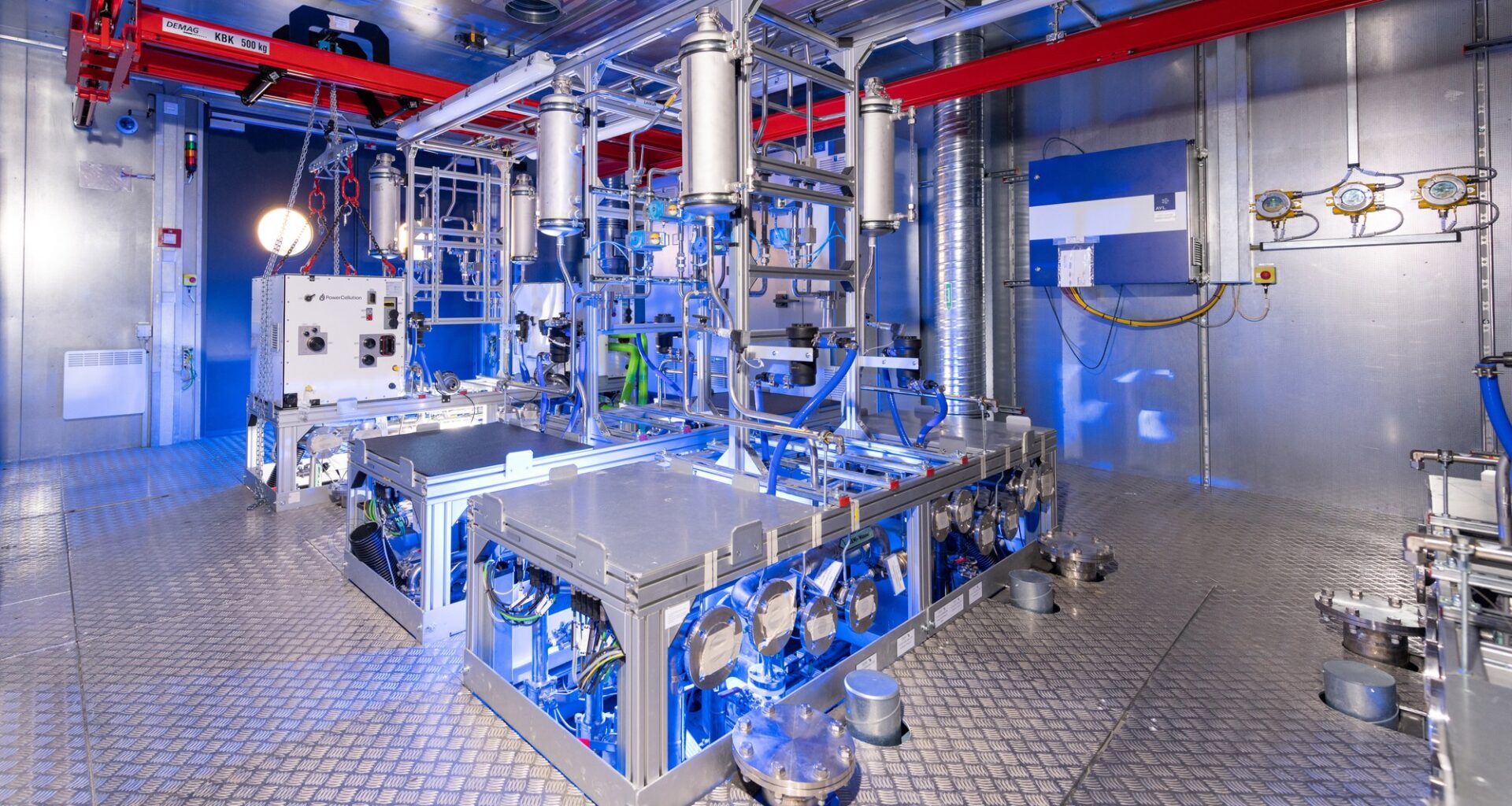

Specifically, the complex and modular BALIS test field makes it possible to comprehensively examine individual components and entire propulsion systems: This includes the fuel cell system itself, electric engines, tank infrastructure and control and regulation technology. Due to its flexible structure and the associated research methodology, the facility is said to be “unique in the world”. All parts of the facility are housed in containers. The DLR Institute of Technical Thermodynamics is responsible for the project.

In addition to setting up and operating the test field, the DLR is also building its own electric propulsion system in the megawatt power class. It comprises a fuel cell system, hydrogen tank, electric engine, control components and power electronics. This makes the DLR one of the first institutions to have such a system. It can be used to fundamentally record, understand and qualify all process steps of a fuel cell propulsion system.

Another research focus of the BALIS test infrastructure is the handling of liquid hydrogen (LH2) in large quantities for the operation of the entire propulsion system. To this end, the DLR is currently building a test tank and the necessary refueling infrastructure with additional funding of around €3 million.

In terms of storage volume, liquid hydrogen has a higher storage density than gaseous hydrogen. Hydrogen only becomes liquid at very low temperatures from -253 degrees Celsius. This is why liquid hydrogen is also known as cryogenic hydrogen. For this reason, the liquefaction, storage and transmission of hydrogen place special requirements on the infrastructure in order to keep the pressure and temperature constant.

For the next three years, the BALIS test environment is already at full capacity with research projects and cooperation projects with industrial partners. Companies with which the DLR is working include start-ups, established medium-sized companies and global players.